EDI(Equality, Diversity and Inclusion)

I reflected on my experience of EDI within the context of my team and the benefits to my team, my team had Andrew from America and Brazil and Ethan from Oxford, and it was an interesting experience meeting people from other countries, but it didn’t affect our team as we were able to work without any stereotypes. I think what most teams need is just the team working spirit, and we truly worked hard . I made sure that every member of the team was treated fairly. I also made sure to recognise, understand, celebrate and value the individual differences of every member of my team.

EDI(Equality, Diversity and Inclusion) Read More »

Blowing the Whistle Dara

Here’s my response to the ethical and professional issue like Blowing the whistle blowing, using a scenario that we had graduated from building a micro mouse and we are currently a registered Incorporated or Chartered Engineer and Member of the IET working on the team supplying driverless cars to a well-known on-demand car-sharing service, that if we discover that the design is flawed and that there is a large probability that one or more of the first production cars will kill a pedestrian. Our team’s responsibilities under the IET’s code of conduct. and the team’s responsibility as a whistleblower.

According the code of conduct on whistle blowing

- Members shall not undertake professional tasks and responsibilities that they are not reasonably competent to discharge.

- Members shall accept personal responsibility for all work done by them or under their supervision or direction. Members shall also take all reasonable steps to ensure that persons working under their authority are both suitably equipped and competent to carry out the tasks assigned to them.

- Members shall assess all relevant liability for work done by them or under their supervision and if appropriate hold professional indemnity insurance. Members whose professional advice is not accepted shall take all reasonable steps:

- to ensure that the person overruling or neglecting that advice is aware of any danger or loss which may ensue; and

- in appropriate cases, to inform that person’s employers of the potential risks involved.

Based on No1- 3 of the code , we would need to let the company know that the design could kill someone as fast as possible and refuse to take more tasks if we are unable tto fix the issue with the probability of killing someone.

Blowing the Whistle Dara Read More »

My Personal Statement of Commitment to Ethical Principles (Dara)

As a member of team Foxtrot, I visited the joint Statement of Ethical Principles issued in 2005 by the Royal Academy of Engineering (RAE) and the Engineering Council as well as the IET. I plan to commit to these principles as a student and in the future as a professional engineer. The statement of Ethical principle is guarded by four principles.

Honesty and Integrity

Based on this principle, I promise to always act in a reliable manner and respect other’s privacy and rights. I shall respect confidentiality when required and declare conflicts of interest to people. I would avoid professional misconduct and improper influence.

Respect for Life, Law, the Environment and Public Good

I would put health and safety first in all that I do and draw attention to hazards, I would make sure that every work that I do is lawful and justified. I would respect and protect personal information; I would protect the quality of built and natural environments.

Accuracy and Rigour

I would always act in care and perform services under competent supervision as a future professional. I would keep my knowledge up to date. I would also identify and manage risks; I would also not mislead my team or allow them to be misled.

Leadership and communication

I would listen to my teammates concern and would also promote diversity, equality and inclusion. I would be objective and truthful in any statement I make, and I will challenge statements or policies that causes concern.

Referring to EC and IET Codes

My Personal Statement of Commitment to Ethical Principles (Dara) Read More »

April Blog

This month was the month where all our efforts finally paid off, We completed the 3d print and the line following code, afterwards we went on a short Easter break. After the break, we were able to complete the combat following code and we started on the special feature, and our special feature was screens with visual images that would change as the mouse moved or changed positions. Unfortunately, we could not get it done in time for our Technical inspection in Greygnog, as it was difficult to add the screen code to our combat code without breaking it. I think we did a great job working as a team,even though we didn’t get the best results.

March Blog

We are getting close to the end of the project and after coding for the micromouse to follow obstacle avoidance and a white line . We noticed the micromouse was still not moving as planned so we had to a number of testing for the infrared sensors and for the input signals as well, there was a lot of soldering and re-soldering on the PCB, the infrared sensors and the white line circuit. It did take a while to find the error as there were many little errors on the PCB, the signals on the board for the motor and the sensors, but we were able to get them fixed luckily with the help of our technicians and Dr Timothy Davies. Also this month we finished the solidworks for our shell and we sent it for printing with the 3d machine. We are kind of in a rush to complete the micromouse as we want it to be good at combat and we are yet to conclude our special feature, so hopefully we finish it all before the trip to Greygnog. See you next month, Thanks for reading

White line Following Progress 2/29/24

For weeks. we have been struggling to get our micromouse to follow the white line accurately and finally this week, we were able to make a breakthrough, our micromouse works although quite slowly and it sometimes stalls. we are glad to have something to build up on. Below is a video of our achievement, and check out our February blogs

White line Following Progress 2/29/24 Read More »

Line Following

Part of the goals for our micromouse is that it must be capable of following a rectangular track consisting of a 50mm white line on a black background. We used the white LEDs on our micromouse to direct the movement around the edge. The LED’s were arranged in a triangle shape with two LEDs on the front and one LED at the back to detect at every location including the back.

Dara’s February Blog

We finished exams last month and we had a short break as well for New Years and Christmas so when we got back for the break, we had our PCBs printed and handed out to us, so Ethan started on it and did a good job soldering. I was giving a role of testing the circuit, and I noticed that the infrared circuit was not working on the PCB as planned so I had to desolder and resolder a few components like the lights. Andrew and I worked on the white light following as well and there were few protypes that ended up being completed and soldered by Ethan, because this month has been quite busy, there weren’t many updates on the website as I would have liked, as we were kind of short staffed. One of our Key members Rhys had to leave due to some unforeseen circumstances, so we all had to chip in to cover up for each other in one way or another. We are also getting close to the end of our micromouse because we have started the design of our shell, more details about the shell will be on the website, I was able to design the tail of the shell, as we are thinking of having a fox shell literally like our name lol. We are also getting our special feature stated soon as we found the components we wanted on amazon.

I think we have done a great job this month, considering so many discrepancies like being a team of 3 all of a sudden, I’ll see you all next month.

Dara’s February Blog Read More »

We’re Back 2/1 /2024(Update).

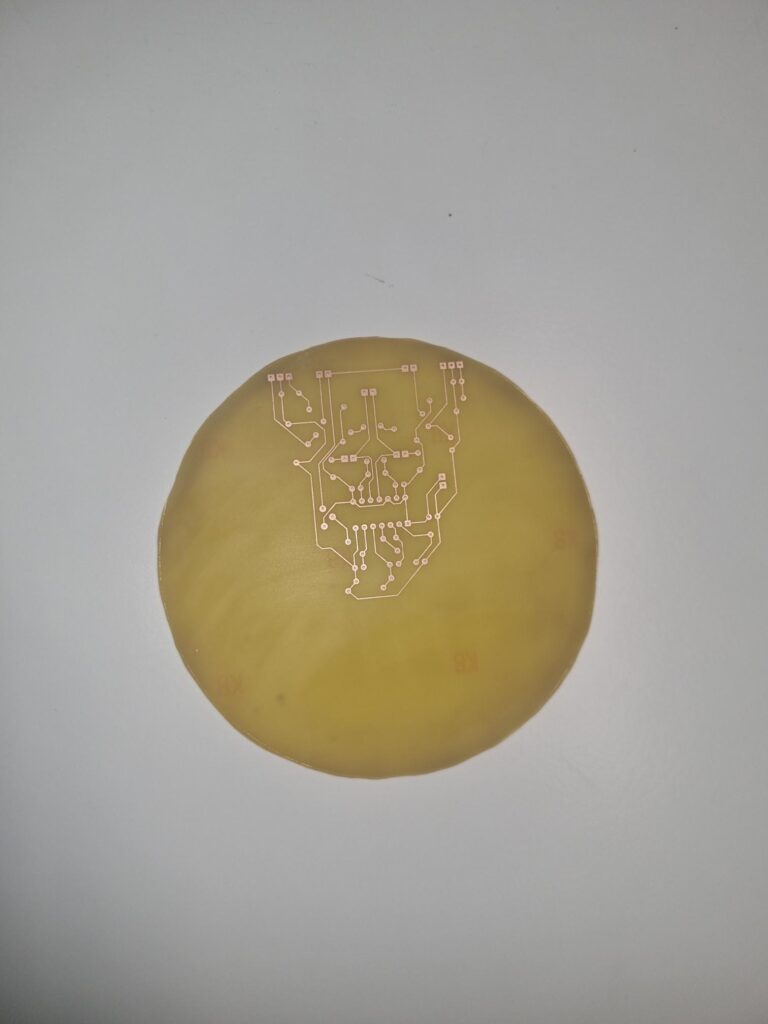

Happy New year! We had a Christmas break and exams from late December to January, and we came back to the labs this week, we designed the PCB before the break and Mr Moody kindly printed it on Tuesday, Ethan started work on the PCB, drilling holes for the circuits and making a smaller circle. Andrew and I also got to work building the white line sensors on the breadboard and then we are currently adding it to the microcontroller. Check out a few pictures from our PCB and white line sensor prototype.

On the left is the first picture of our PCB after drilling holes for the circuit, the edges are still a little rough.

On the right is the final picture of the PCB after using the sander to get a more accurate circle.

We’re Back 2/1 /2024(Update). Read More »